WHY eParking solar ?

There are approximately 300 Millions parking places in Europe and 2 Billions in USA !

Imagine using this huge amount of already urbanized spaces to address the 3 major issues of energy transition :

Renewable Energy

Today, energy is not only produced from non-renewable resources but is also a major contributor to CO2 emissions.

eV charging

A shift to electric vehicles necessitates the utilization of clean electricity and expansion of accessible and affordable public charging facilities.

Grid balancing

The growing affordability of renewable energy sources often faces hurdles due to the limitations of the existing electrical grid capacity.

HOW eParking Solar is achieving this ?

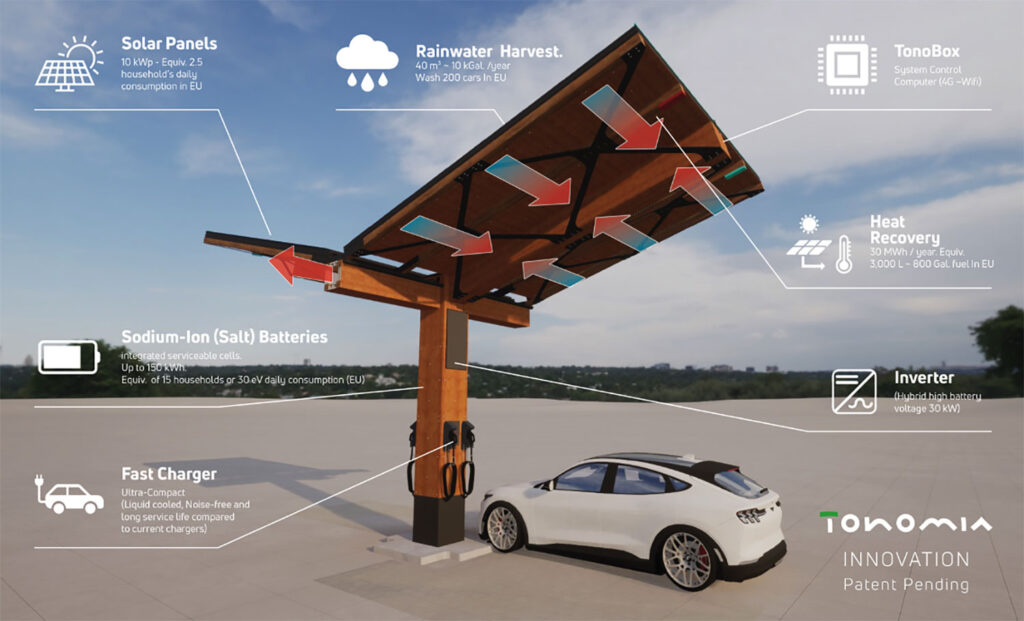

Car Parking lots are located close to buildings. The all-in-one eParking solar module developed by Tonomia, produces solar electricity and heat to feed surrounding buildings, stores excess electricity in Sodium-ion or lithium batteries, to fast charge eVs or balance the grid, while recovering rainwater for sanitary usage or car washing.

The eParking Solar module stands out with eco-friendly materials, AI-driven quality control, and user-friendly interfaces, setting a new standard in sustainability and innovation for parking solutions.

The all-in-one eParking solar modules will revolutionize parking infrastructures by integrating sustainable energy and advanced technologies whilst offering high revenues for parking operators and comfort and convenience for vehicle owners.

Ultra-modular, flexible and cost-effective the eParking module has been designed for 2 to 4 parking spaces and can be deployed independently in any quantity for full terrain coverage, unlike our competitors who need a redesigned batch system.

eParking Solar is subject to 6 patents with more than 300 innovative elements

WHAT technologies, exactly?

Photovoltaic panels

eParking utilizes advanced photovoltaic panels from reliable brands to ensure efficiency and reliability. The 4-place solar module comprises 16 panels, pre-assembled in strings of four with a heat recovery system, addressing three major issues in traditional solar panel installations:

- Installation Time: The design and use of lifting equipment expedite the installation process.

- Handling Difficulty: The solar assembly is easy to handle and less strenuous for workers, overcoming restrictions like Germany’s limit on panel size.

- Pedestrian Safety: The solar modules are positioned above the heat recovery board, acting as a protective roof for pedestrians, negating the need for specific safety designs mandated by Germany’s code.

Performance-wise, eParking can achieve up to 10 kWp power with an annual production of 10 to 15 MWh, depending on geographical location. In Belgium, this output can meet the energy needs of approximately 2.5 households.

Sodium-ion or Lithium Battery

Battery storage is central to eParking’s innovation, providing multiple benefits. The battery stores excess energy for later use and enables fast charging without requiring grid upgrades. eParking Solar employs high energy density chemistry, focusing on sodium-ion batteries due to lithium scarcity concerns. Sodium-ion batteries rely less on scarce materials and are serviceable at the cell level, fully integrated into the main pillar to reduce costs. Each battery cell is managed by a Battery Management System (BMS) and monitored by 80 temperature sensors for optimal thermal management, with live data accessible via a digital platform.

The battery temperature is maintained optimally by a water reservoir within the solar module. Recent upgrades have enhanced battery capacity to 320 kWh for lithium and 200 kWh for sodium, equivalent to the daily electricity consumption of 30 households or 60 cars.

SolarHeat recovery

Heating can account for up to 37+% of greenhouse gas emissions in a country (UK for example).

Solar panels transform solar energy into 20% electricity and 80% heat.

10 kW electricity means 30 kW potential heat recovery or 30 MWh/year (3,000 L fuel equiv.). Solar boilers were actually the most used equipment to harvest energy before affordability of photovoltaic panels.

Even though the thermal energy production is much higher in summer where space heating is not required , It has been proven that sun heat could cover up to 50% of home heating needs at a fraction of the cost of conventional solutions.

This is why eParking is designed with a very smart heat recovery system combining non-metallic materials (wood) and vacuum insulation panels and avoids the need for sophisticated liquid solutions with mitigation energy losses in the way.

Fast DC charger

eParking makes fast charging intallation an easy process by removing these 4 major road blocks :

- They require a high power grid, which is not always available.

- They are extremely expensive (1000 to 1500 USD/kW).

- They are very noisy during high-temperature conditions.

- They are often unreliable.

How eParking is doing that ?

- Storing energy in high-capacity batteries, charging them at low speeds, and releasing energy to vehicles at high speeds, eliminating the need for a high-capacity grid connection.

- Integrating charger components within the eParking module to reduce system and installation costs.

- Utilizing liquid-cooled fast charging, which is noise-free and doubles the service life of chargers.

eParking Solar chargers can be configured in various setups:

- 4 x 40 kW DC: Charges 4 cars in 2 hours, ideal for European shopping centers.

- 2 x 80 kW DC: Charges 2 cars in 1 hour, suitable for US supermarkets.

- 1 x 160 kW DC: Charges 1 vehicle in 30 minutes, ideal for locations requiring ultra-fast charging such as motorways, airports, and train stations.

- 2 x 11 kW AC: For long-duration parking like offices and factories.

- No Charger: Modules can be upgraded as the electric vehicle fleet grows.

eParking uses the open-source EVEREST platform developed by PIONIX for charging management.

Rain Water Harvesting

All in one Smart Box

- CAN Bus: to communicate with inverter, battery chargers,

- Modbus: to control lighting and car presence detection or any RS485

- I2C Interface is used to control the thermal cameras

- Relay Control System: to control the heating cables

- MOSFET Control: to activate the water pumps

- PWM (Pulse Width Modulation): to control the ventilation fan speeds

- WiFi: to connect devices to the network servers

- 4G/5G Networks: to communicate with chargers and when internet is not available via wifi

- HDMI : to connect the Tonobox to the display screen

- USB : to connect to a computer.